In February US President Barack Obama gave his Stare of the Union address as he does every year. In the speech, he recognises the potential of 3D printing.

Our first priority is making America a magnet for new jobs and manufacturing. After shedding jobs for more than 10 years, our manufacturers have added about 500,000 jobs over the past three. Caterpillar is bringing jobs back from Japan. Ford is bringing jobs back from Mexico. And this year, Apple will start making Macs in America again.

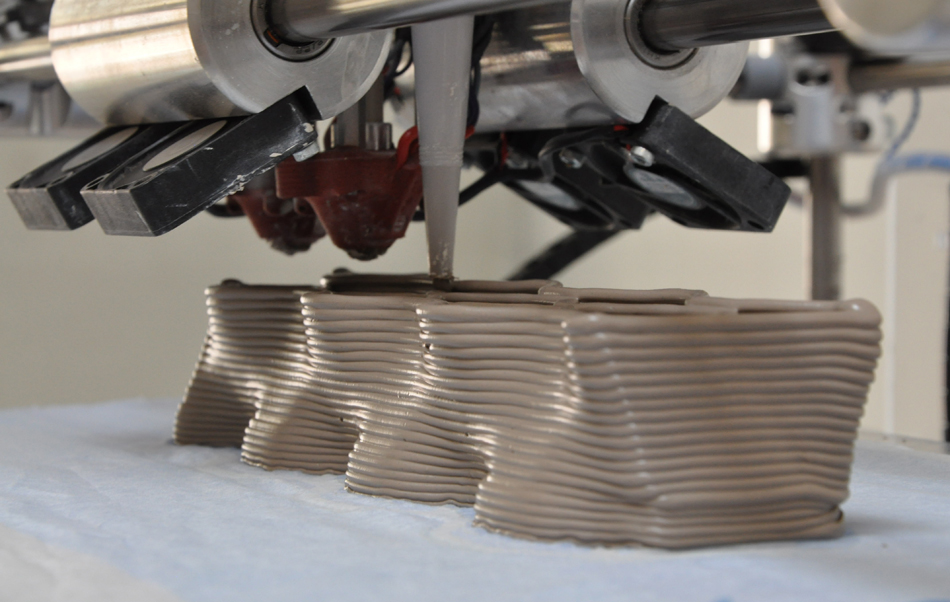

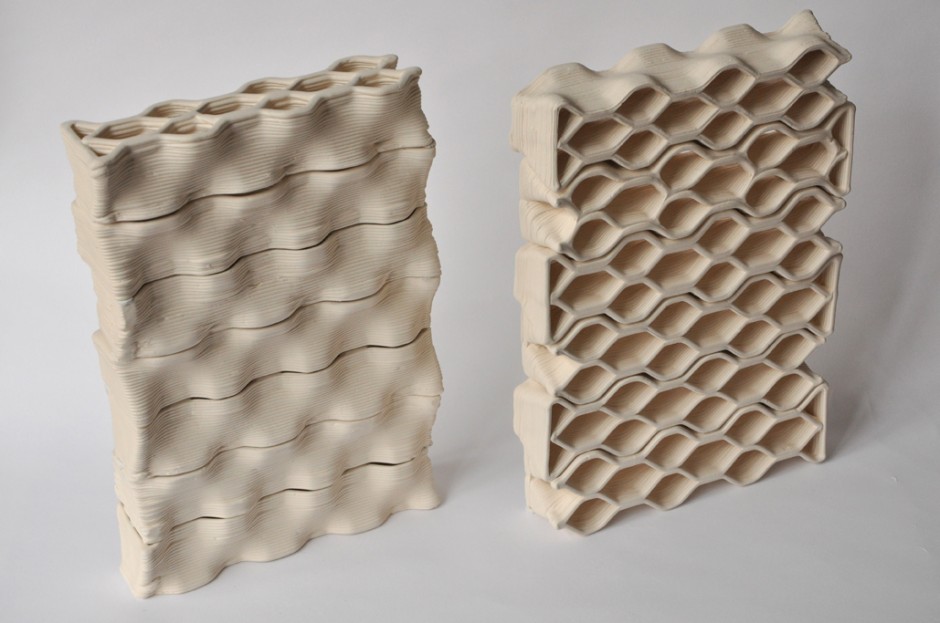

There are things we can do, right now, to accelerate this trend. Last year, we created our first manufacturing innovation institute in Youngstown, Ohio. A once-shuttered warehouse is now a state-of-the art lab where new workers are mastering the 3D printing that has the potential to revolutionize the way we make almost everything. There’s no reason this can’t happen in other towns.

So tonight, I’m announcing the launch of three more of these manufacturing hubs, where businesses will partner with the Department of Defense and Energy to turn regions left behind by globalization into global centers of high-tech jobs. And I ask this Congress to help create a network of 15 of these hubs and guarantee that the next revolution in manufacturing is made right here in America.

The US president makes a State of the Union address every year to report on the condition of the nation and to outline their legislative agenda.

It’s always good to see the government recognise the potential of a technology and help it along. Even if it’s not my government.